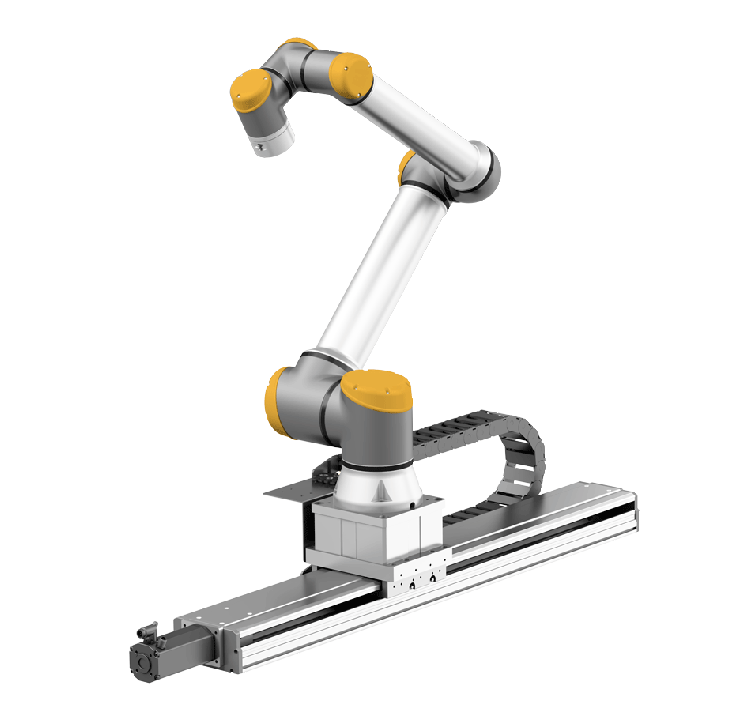

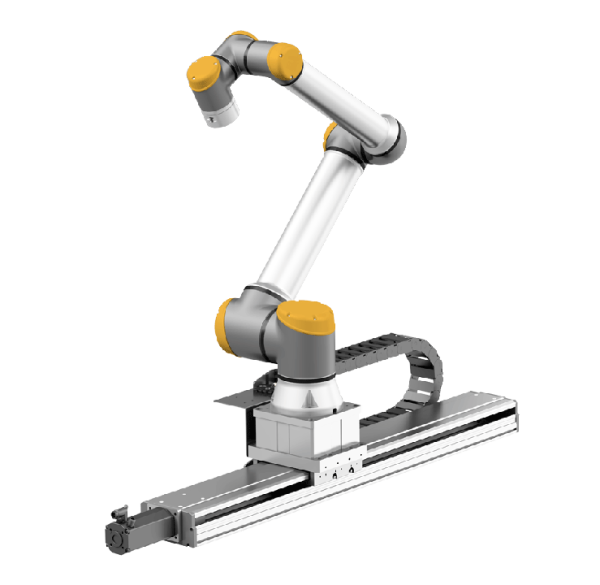

Mô tả

Slidekit Linear axis for collaborative robots, plug and play. Moreover, SLIDEKIT is also available with a general purpose variant, using simple digital I/Os to control the motion, making it compatible with other cobots brands.

Cobots combined with the SLIDEKIT 2.0 linear module provide a cost-effective solution to upgrade an existing assembly shop, moving from a manual handled to a fully automatized line.

The 2.0 release of the SLIDEKIT delivers several improvements compared to the former version, like higher system reactivity and stability, lower noise in operation and optimized design for limit switches and re-lubrication points.

Slidekit Linear axis for collaborative robots, plug and play

Benefits:

- Increase the operating range of a cobot

- Compatible with Universal Robot range UR5 to UR16

- No hardware/software development needed

- Direct positioning access within a UR controlled environment

- Fast positioning to increase productivity and save costs

Features:

- UR+ certified horizontal positioning axis

- Ready to use complete system solution

- Software plugin (UR Caps) to UR control system included

- High level of positioning precision and repeatability

- Very low noise in operation

| EWELLIX SLIDEKIT | SLIDEKIT-UR | SLIDEKIT-UR-BELT |

| Accuracy (mm) | ± 0,01 | ± 0,08 |

| Max dynamic payload (N) | 10 900 | 10 900 |

| Max stroke (mm) | from 100 to 1800 | From 100 to 3000 |

| Operating temperature | 0 to +50 °C | 0 to +50 °C |

| Max. linear speed (mm/s) | 1 000 | 1 000 |

| Drive type | Ball screw | Belt |

| Duty cycle (%) | 100 | 10 |

Linear axis for collaborative robots (slidekit for cobots)

Several applications require to cover long distances to perform the operation, like finishing, welding and parts inspection.

These repetitive tasks, usually done manually, are time consuming and with low added value for the operators.

By adding a linear module as a dynamic base for the robot, it is possible to extend the handling operating area of the robot, increasing the productivity and output quality.

The SLIDEKIT 2.0 provides quick and fast installation, by having a standardized mechanical, electrical and software interface with Universal Robots.

In few steps, the system is ready to be used and simply programmed in operation.