Mô tả

- Load up to 1,5 kN and speed up to 80 mm/s

- Stroke up to 1 400 mm

- Plug and play with Universal Robots and Omron collaborative robots

- Compatible with other cobot brands via TCP/IP protocol

Benefits:

- Extend cobot operating range to increase productivity and save costs

- No hardware/software upgrades required

- Direct positioning access within the cobot control environment (where available)

- Vibration-free movement

- High positioning precision

Features:

- Certified UR and Omron positioning axis

- Ready-to-use complete system

- Robust column design for industrial use

- Silent operation

- High stiffness

| Push load |

1 500 N

|

|---|---|

| Pull load |

0

|

| Max stroke (mm) |

500 to 1 400 mm

|

| Operating temperature | |

| Type of protection |

IP 40

|

| Max. speed no load (mm/s) |

80 mm/s

|

| Duty cycle (%) |

10

|

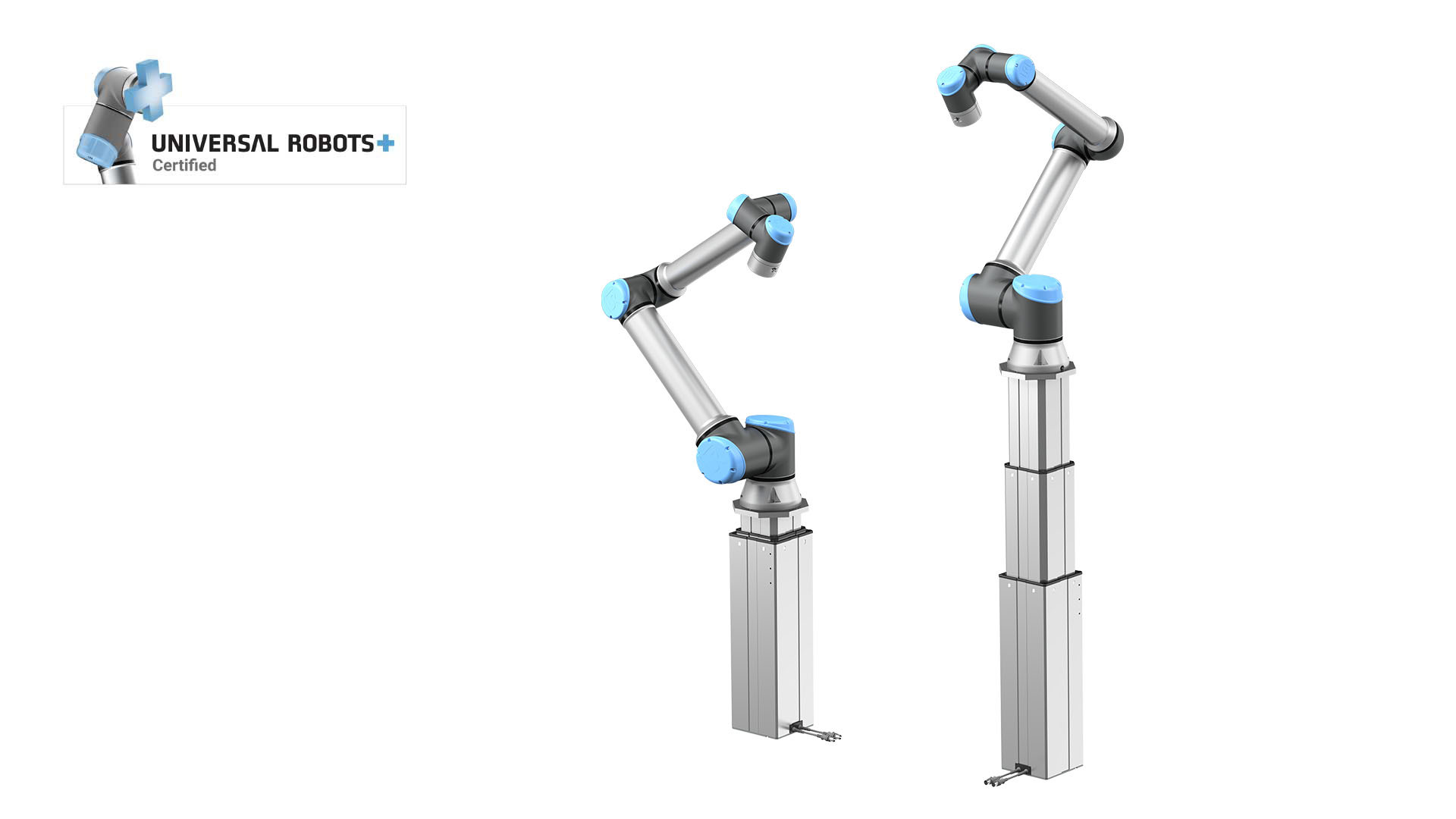

Cobots are often used for palletising but reach their limits as soon as the pallet stack reaches a certain height. The easy-to-assemble LIFTKIT increases the reach of the Cobot by moving it along a vertical axis.

The base of the Cobot can be raised or lowered during palletising so that it is always in an optimum working position. This increased range improves productivity and reduces costs.

Ewellix LIFTKIT is a ready-to-install system and includes a lifting column with a cobot mounting interface, a controller and a software plug-in for compatible robots so that movements can be programmed directly via the cobot controller.

For non-compatible collaborative robots, the LIFTKIT-0S version allows to control the column through standardized Ethernet TCP/IP interface. With a set of simple commands, it’s possible to connect the LIFTKIT to virtually any type of cobot and create a dedicated program to perform the lifting function.

LIFTKIT-UR 7th axis for cobot UR

Benefits:

- Extended operating range of UR cobots to increase productivity and save costs

- No hardware/software upgrades required

- Direct positioning access within the UR control environment

- Vibration-free and virtually maintenance-free movement

Features:

- Certified UR+ positioning axis

- Ready-to-use complete system

- Software plugin (UR Caps) for UR control system included

- Robust column design for industrial use

LIFTKIT-OM Liftkit – 7th axis for cobot omron

Benefits:

- Extended operating range of Omron cobots to increase productivity and save costs

- No hardware/software upgrades required

- Direct positioning access within the Omron TM control environment

- Vibration-free and virtually maintenance-free movement

Features:

- Certified Omron plug-and play positioning axis

- Ready-to-use complete system

- Software plugin Omron TM control system included

- Robust column design for industrial use

LIFTKIT-TM Liftkit – 7th axis for cobot Techman

Benefits:

- Extended operating range of TM cobots to increase productivity and save costs

- No hardware/software upgrades required

- Direct positioning access within the TM control environment

- Vibration-free and virtually maintenance-free movement

Features:

- Certified TM plug-and play positioning axis

- Ready-to-use complete system

- Software plugin TM control system included

- Robust column design for industrial use