Máy hàn siêu âm SCHUNK

Hiển thị 1–12 của 14 kết quả

-

Máy hàn siêu âm FX20-2L-R

The FX20-2L-R is suitable for ultrasonic welding of power electronics (e.g. IGBT modules) or cell contacting systems (battery applications). The machine is a fully automated system. -

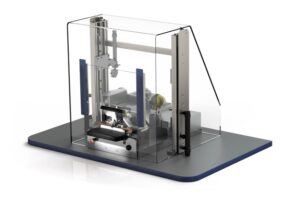

Máy hàn siêu âm FX20-L

The FX20-L is suitable for ultrasonic welding of power electronics (e.g. IGBT modules) or cell contacting systems (battery applications). The machine is a semi automated system. -

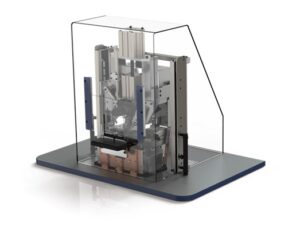

Máy hàn siêu âm DS20-S-plus

The manually operated ultrasonic welding machine DS20-S-plus is based on a flexible concept and is suitable for laboratories, prototyping and small series production of e.g. power electronics or special applications. -

Máy hàn siêu âm Kobra-III

The Kobra-III is the latest development in the Kobra series for gas-tight welding of copper tubes from refrigeration circuits. The machine is extremely compact – especially in the welding area it is very narrow so that it can be immersed very well. Fields of application are for example the refrigerator and air conditioning industry. The Kobra-III is CE-compliant as standard and is also available as an Ex-certified version as an option. The system is supplied with a Windows-based software system that can be integrated into networks. -

Máy hàn siêu âm Kobra-II

The Kobra-II is used for gas-tight welding of copper tubes in refrigeration circuits. The machine has an output of 3 kW and is suitable for tube diameters of up to 10 mm with a wall thickness of up to 1.0 mm. An optional barcode scanner is available for the traceability of individual welds by serial number. The handles can be selected from several different variants. -

Máy hàn siêu âm LS-C

The LS-C is suitable for welding numerous terminal applications, such as connecting copper or aluminium cables with different contact parts, tubular cable lugs or bus bars. -

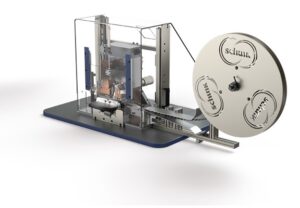

Máy hàn siêu âm L-Splice 100/200

The L-Splice is designed for welding splices in the upper cross-section range of up to 100 mm² or 200 mm². The L-Splice is well suited for both manual operation and integration into a fully-automated production system. There are two different design variations available for optimal ergonomic operation. Regardless of which model you choose, machines of the L-Splice series are built to withstand high thermal and mechanical stress. Further cross-sections and applications are possible – please contact us. Industries: Automobiles Construction equipment Transportation -

Máy hàn siêu âm DS20-II

Appearing on the scene in 2011, the DS20-II was a quantum leap in wire-harness production: For the first time it became possible to weld wires with cross sections of up to 120 mm² to terminals. The possibilities include, for example, the connection of Cu and/or Al wires with different contact parts with a precision that is unique for this area of application. -

Máy hàn siêu âm DS20-GT

Whenever the subject is ground terminals in the wire-harness industry, there is no getting around the DS20-GT. It is an old hand and bench mark at the same time. While the core competency initially was especially the splicing of wires with small cross sections, splicing wires with cross sections of 1.5 mm² to 25 mm² to terminals no longer presents a challenge. -

Máy hàn siêu âm DS20-III

The DS20-III is a machine for welding strands on terminals. All common terminals can be welded with the DS20-III, not only in copper, but even in aluminium. Thanks to a completely renewed hood concept, the machine is 360° accessible and therefore very easy to maintain. -

Máy hàn siêu âm GS-50

Special features: CE-conform (Plus Version) Windows 7 operating system Self-explanatory user interface (Office like) Touchscreen monitor (optional) Comprehensive process monitoring and documentation Network compatible Linkable to superordinate ERP systems, e.g. customer-specific wire harness production Dynamic adjustment of target values and statistics functions Welding chamber illumination (optional) Improved splice setup via insertion aid (ASSK) Designed for table setup Numerous table variations are optionally available Plug & Play functionality due to integrated ID chip High-precision digital position-measuring system for recording splice geometries Ultra- rapid sequence welding Cross section range 1,5 mm² to 50 mm² Various user levels and access management via key switch Suitable for Al, Cu wires and cascade welding -

Máy hàn siêu âm GS-40

The Global Splicer (GS) is designed for welding splices in the mid-sized cross-section range of up to 40 mm². Despite their expanded cross-section range, these devices are constructed to be both compact and robust. Further cross-sections and applications are possible – please contact us. Industries: Automobiles Construction equipment Transportation Household appliances / white goods